Finite element processors have been greatly improved over the years. It has come to the point that inexperienced users with little training can create meshes that on the surface seem to be all right. But when is all right good enough, does the quality of your mesh even matter that much at all? The simple answer: yes it does matter. A low quality mesh lowers the accuracy of FEM results, to the point where you can no longer draw meaningful decisions from the output of your finite element model. This applies across engineering domains such as offshore structural engineering, engineering of rotating equipment or lifting equipment. The quality of the mesh is good enough when the accuracy of the produced results is high enough. That is of course, when all the other inputs to the model are also accurate enough.

Mesh Quality Metrics

There are multiple metrics to control the quality of elements. An important one is the mesh density. A smaller element size will produce more accurate results, assuming there are no singularities present in the mesh. However, refining your mesh will result in longer run times and more required memory. This is especially problematic when your analysis requires multiple-iteration runs, as is often the case in transient, non – linear analyses or parametric runs.

Mesh element types

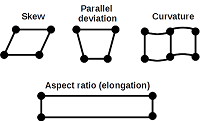

Type of element used and shape are also important factors affecting the overall meshing quality. Hexahedron mesh elements tend to produce marginally better results than a tetrahedron mesh and is less computational intensive, but hex mesh is generally more difficult to implement. Poor element shapes often lead to convergence problems and inaccurate results. Multiple shape metrics can be used to evaluate element shape quality. These include aspect ratio, parallel deviation, mid node position, Jacobian ratio, corner angle, skewness and orthogonal quality. Some examples of these metrics are shown in Figure 1 below. Proper FEM software packages that our engineers use like ANSYS for example, include methods for such element shape evaluation.

Figure 1: Element shape metrics

Impact of Mesh Quality on Result Accuracy

Knowing what influences mesh quality is all nice and well, but how big of an impact does a difference in quality have on the final results? To demonstrate this, we can observe the example seen in Figure 2. A bracket model with the bottom fixed and a downward force applied on the top right edge, is meshed with two different densities. Note how not only the maximum stress output changes from roughly 7.5 MPa to 9.5 MPa (>26%), but also the location of the maximum stress is different in both situations. This demonstrates the importance of a finer mesh density for making the right conclusions on design weak points and necessary optimizations.

Figure 2: Difference in mesh density

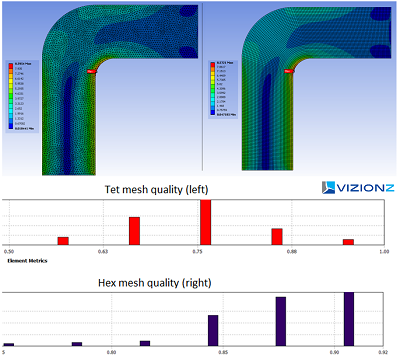

A second example (Figure 3) uses the same geometry, but different element types. The element metrics (quality) is higher for hex mesh. The difference in stress is small, but this difference may increase in more complex geometries and models.

Figure 3: Difference in mesh type

Summarizing, the mesh quality is one very important factor to the overall accuracy of your model. It can make the difference between useful or meaningless results. Keep in mind that your mesh is always associated to the physics problem you are trying to solve, not necessarily the geometry. Selecting the right mesh quality metrics is essential in controlling the quality of your FEM model and in choosing the right actions to improve it. These are considerations that we take into account on a daily basis for our clients so if you have any questions, mail or call us. We are always more than happy to address them.